MRG Design and Function

State transportation departments use median responder gates (MRGs) to reestablish the median crossovers removed during concrete barrier installation. MRGs are fast-acting, retractable gates that open wirelessly on demand to allow emergency responders time-saving access through concrete barriers to opposing traffic lanes. MRGs can also be used to redirect stalled traffic or for temporary construction purposes.

First responders and other personnel activate MRGs using handheld wireless transmitters. When emergency personnel move within approximately 300 feet of the MRG, they can press on a handheld wireless transmitter to initiate the opening process. After driving through the gate, personnel also use the transmitter to close the MRG. The responder gate opens in approximately 10 seconds and closes in approximately 15 seconds, thus creating less responder travel time, reducing precious life-saving minutes needed to reach, treat, and transport casualties.

Specifications

Our MRGs are equipped with high-visibility warning lights to signal various gate-operating modes. When operators initiate the opening sequence, warning lights flash red until the gate fully lowers. Once completely open, the red warning lights will stop and yellow lights flash indicating that it is safe for emergency vehicles to travel through the median barrier onto the opposing travel lane.

The median barrier gate comes integrated with a self-contained, state-of-the-art, 24-V, solar-powered system capable of gate operation without external power. The solar-powered battery unit delivers power to the motor, driving the responder gate with 9000 lbs of force to help overcome ice and snow. The MGR’s drive consists of a drive shaft, sprockets and sprocket chains.

Built-in safety systems such as overload and sufficient power protection ensure the longevity of the motor and other internal systems. A limit switch setting device aids in setting limit switches without trial-and-error gate movement and counterweights reduce energy requirements. The microprocessor-controlled gate system also possesses vehicle occupancy sensors that prevent unfortunate incidents caused by inadvertent gate operation while vehicles move above the lowered gate.

We built and crash tested our MRGs in compliance with the American Association of State Highway and Transportation Officials (AASHTO) Manual for Assessing Safety Hardware (MASH) Test Level 3 (TL-3). MRG’s durable design was also on display during the crash test. The MRG absorbed the crash test vehicle energy with no deflection and continued to operate reliably after the crash sustaining only minor damage.

MGRs can be installed in new or existing concrete barriers, and states are eligible to apply to the Federal Highway Administration (FHWA) for reimbursement under the Federal-Aid Highway Program control number B-216A.

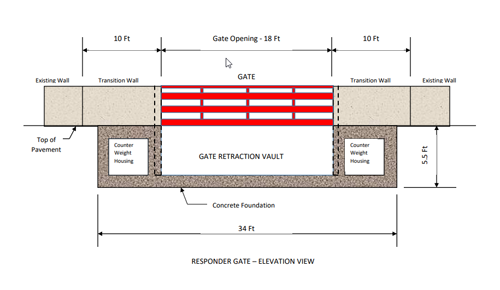

- Gate Height above Pavement – 50”

- Bottom MRG Foundation below Pavement – 5’-6”

- MRG Overall Length – 38’–0”

- MRG Foundation Width – 4’–9”

- Shipping Width – 6’–3 3/16″

- Shipping Height – 9’-1 3/8″

- Shipping Length – 30’-1 3/4″

- Gate Width at Top – 12”

- Gate Width at Bottom – 1’-3 11/16″

- Gate Opening – 18’

- Gate Weight – 3007 lbs

- Shipping Weight – 9018 lbs

- Counterweights – 2 @ 2918 lbs. each

- MRG Electrical System – 24 Volt DC

- Drive Force – 9,000 lbs

- Gate Lowering Time – Approximately 10 sec

- Gate Raising Time – Approximately 15 sec

Cumberland’s MRG Utilizes Old and New Technology

Our MRGs offer superior performance that will improve the response time of your community’s emergency and maintenance vehicles. We use several features from cutting-edge technological programmable controllers and solar power to a time-tested counterweight system that allows gravity to minimize the MGR’s energy requirements. This innovative combination allows our products to meet your first responders’ rigorous demands.

All our features and specifications specifically aim to reduce responder travel distance, thus reducing the time for first responders to reach their target location. If you would like to know more about the features and specifications of our MRGs, contact our support team or download our resources today!